View Case Study

Large Nickel Concentrator Plant - Xanthate dosing control valves upgrade.

Instrowest was contacted one of Australia’s largest miners to assist with reagent dosing at their largest nickel operation in Western Australia.

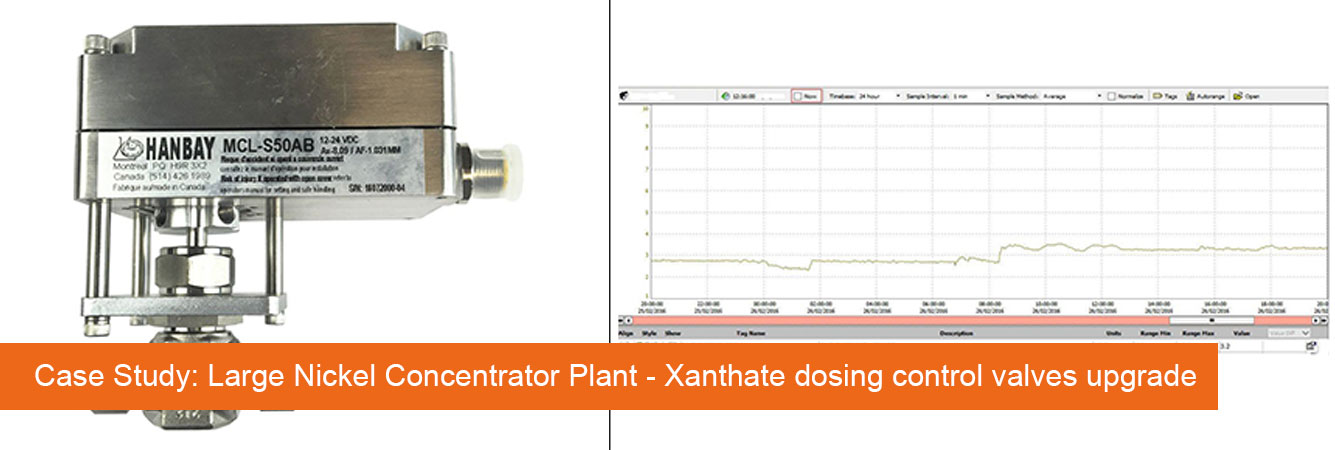

The scope was to provide a solution for the issues they were experiencing with the dosing of Xanthate into their process. They were previously using GEMU control valves, which were 110VAC powered and controlled by a 4-20mA analogue signal. The issues site had with these were that the valves was that they failed quite regularly and were a very expensive valve/actuator to replace. Another issue they were experiencing was the very erratic control during operation, resulting in over and under dosing of xanthate to the process.

You can see from the figure above that dosing of these small flow rates was very erratic due to the valves proportional gain causing a “Hunting” trend that doesn’t quite match the set point.

Instrowest proposed the use of a Hanbay multi-turn actuator and metering valve, sized with a flow coefficient that would allow precise dosing control of the Xanthate as low as 100ml/ min. These Hanbay actuators and valve combinations were less than two thirds the price of the valve previously fitted and have proved very reliable on many of our other sites.

The Client initially decided to trial 3 Hanbay actuators and valves, along with a power supply (110VAC to 24VDC) which was also required to power the new actuators.

“These Hanbay actuators and valve combinations were less than two thirds the price of the valve previously fitted”

Results:

The Clients maintenance and metallurgical personnel are extremely happy with the results of a 6 month trial of the Hanbay actuators being used onsite. From an operational perspective, less human intervention is required to make adjustments to the automatic control of the dosing system. From a maintenance perspective there have been no incidents of breakdowns. Lastly, the Metallurgists on site are extremely happy as reagent use on site has decreased significantly from minimising reagent overdosing, as well as gaining better process recovery.

Since the initial trial of 3 Hanbay actuators and valves, they have purchased another 6 of the same size and have indicated they are also interested in installing them in other parts of the process also.

Instrowest have had great success with these actuators and when used in conjunctions with suitably sized and selected valves we have been able to achieve excellent process and flow control on a number of different fluids.

If you would like Instrowest to assist with your next project please contact us.

Email: sales@instrowest.com.au

Website: www.instrowest.com.au

Tags:Hanbay Actuators, Electric Valve Actuator, Instrument Installation, Calibration Services

Login/Signup

Login/Signup